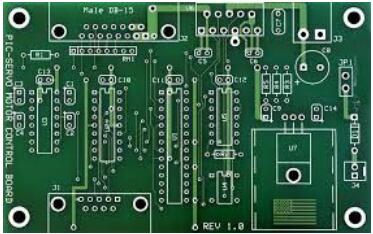

PCB is an abbreviation of Printed Circuit Board, which is an important electronic part to load electronic components and connection carrier of electronic components conduction. Why called is due to fabrication with a printing technology.

PCB is classified as single layer, double-sided and multilayer in terms of circuit layers. Multilayer PCB with 4-layers and 6-layers is typical. More complex multilayer PCB has up to dozens of layers. It is also can be divided into rigid board, flexible board and flex-rigid board. Printed board evolved from single layer to double-sided, multilayer and flexible board, retaining respective development tendency.

Drived by continuousness of high precision, high density and highly reliable direction development, volume reduction, costs reduction, performance improvement, printed circuit board still maintains a strong vitality in the future development of electronic equipment.

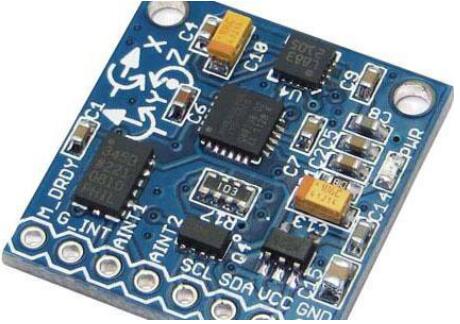

PCBA is simply known as printed circuit board & Assembly, in other words, the whole manufacturing process of electronic components being soldered onto bare PCB boards through SMT and DIP technologies. The standard term is PCB'A in Europe and USA.

What's more, SMT assembly process stands for electronic components being soldered onto blank PCB boards, which includes solder paste printing, soldering SMD components, re-flow oven soldering, AOI, wave soldering and QC inspections. DIP means an engineering process of soldering the component that can not be hanlded by SMT mounters and should be soldered by wave soldering and manual operations such as pin-cut. As herein, big part of PCBA manufacturing has been completed and subsequently we have to manage programming and test, until to the end.